Thin sections

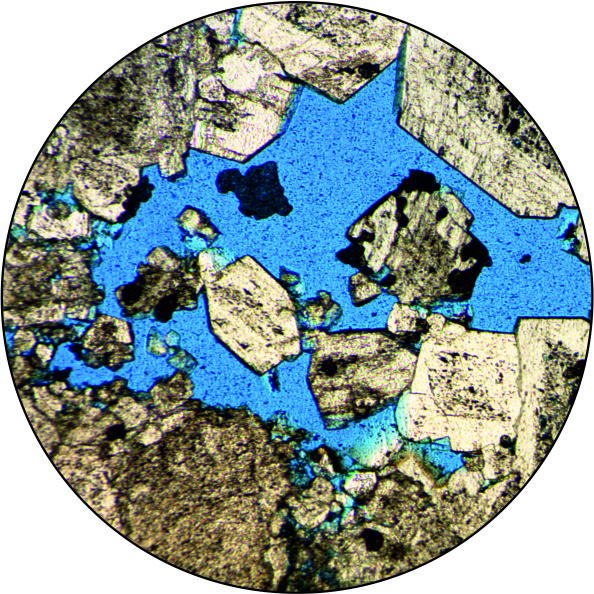

All we know that the best results of geological research of thin sections are the main purpose of geologist in the world. This require the best thin sections for such scientific researches also minimal losses of geological material. Since 2012 we are selling our products and services in the Europenian Union especially Poland, Denmark, Sweden, Finland, Germany and Norway also we got customers from Africa and Asia. For commercial companies we are preparing special thin sections impregnated for petrography analysis of granites, gravels and sands for concrete and asphalt production, also in Norway we are cooperating with geological consulting companies in oil and gas sector (we are preparing unstandardized large thin section with blue dye impregnation). Morover we are producing the geological thin sections for archeologic research (ancient glass, pottery and architecture bulidings) also we are cooperating with geological survey in meny countries in the Europe, universities and museums. For thin section preparation we are using only high quality of materials.

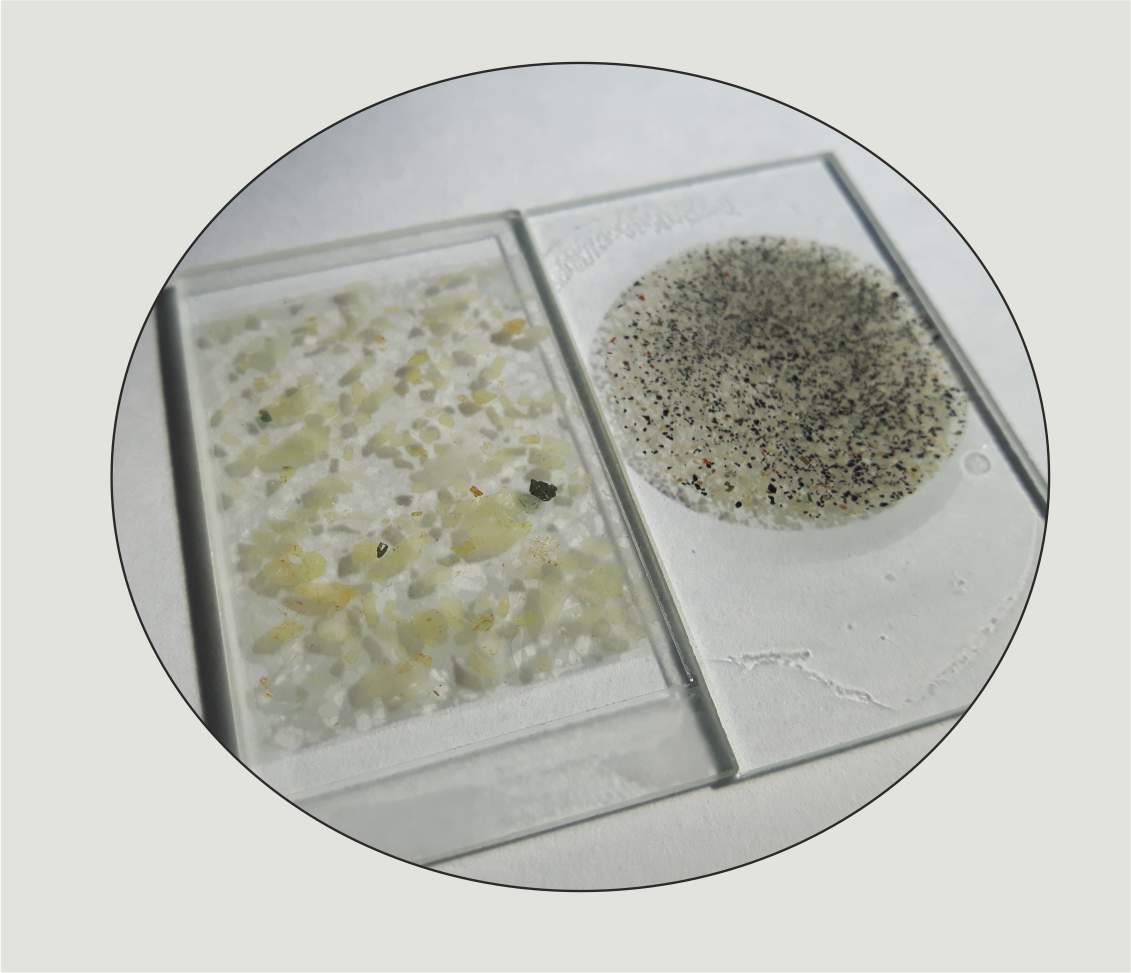

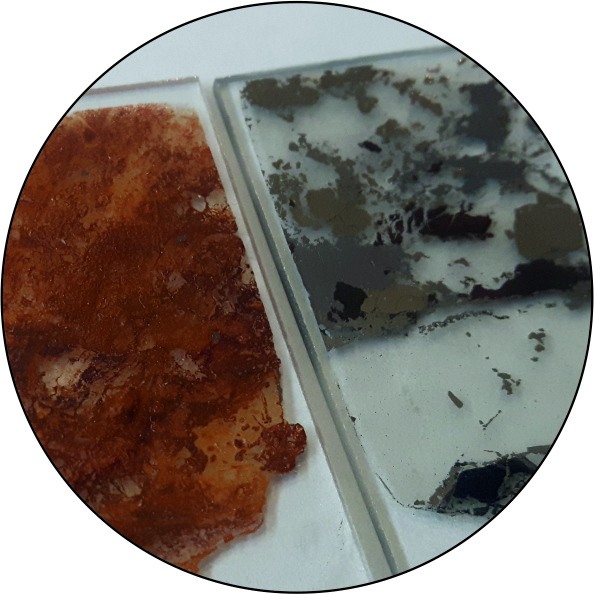

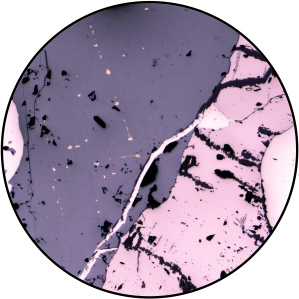

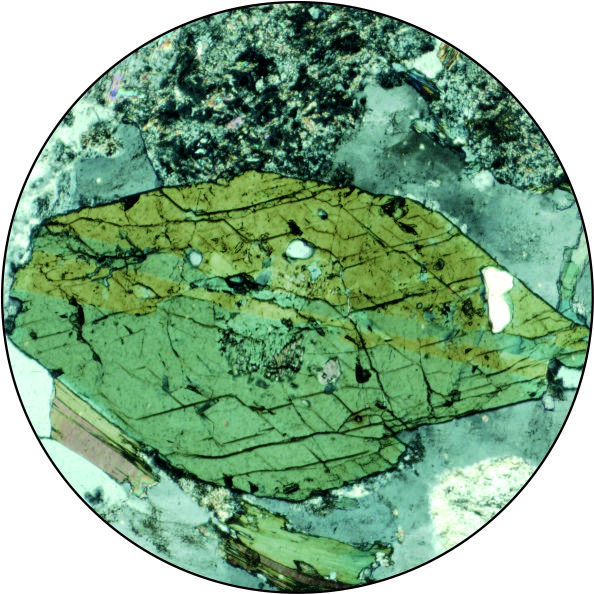

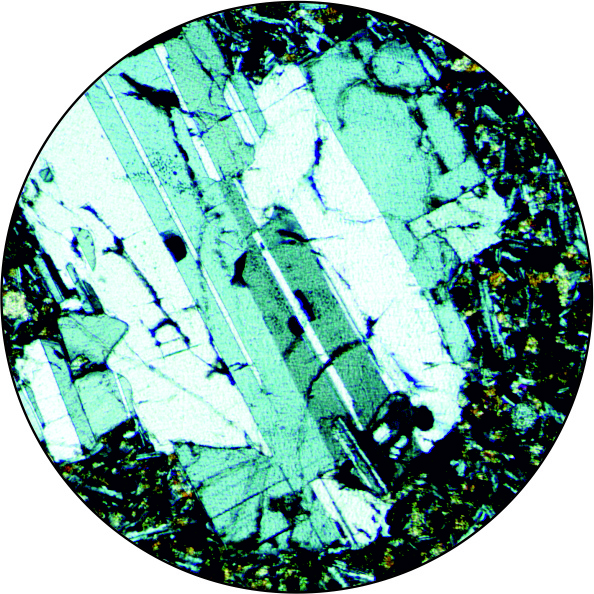

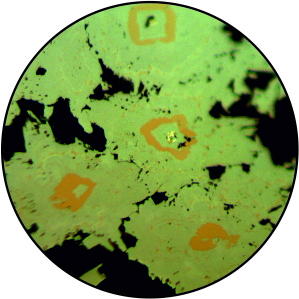

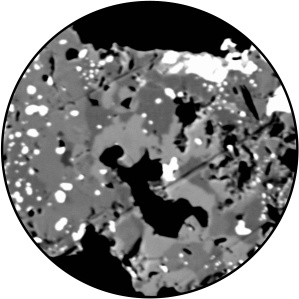

- Thin sections gallery

- Thin sections general description

- Thin section price cataloque 2019

Thin sections petrography

Around 1851, A. Oschatz and H.C. Sorby started making thin sections of rocks to study in microscopes. Sorby wrote many papers on this topic, emphasizing the use of polarized light. He also designed a spectroscope for use with microscopes.In 1867-69 the U.S. Congress sponsored a comprehensive scientific study on a cross-section of the country, along the 40th parallel. F. Zirkel carried out the petrographical part of this project, his large report appearing in 1876. It contained large color illustrations of 44 thin sections, which received much attention. Many geologists became interested in making use of this technique. Since 19th century thin sections have 30 microns but the technique is more precise. Now the polished surface can be almost flat using supersonic ultrawawer or very fine dimonds for polishing.

Petrography is the branch of geology that involves the detailed description and classification of rocks based on their mineralogical composition, texture, and structure. Thin section analysis is a fundamental technique in petrography, providing invaluable insights into the characteristics and origins of rock samples. Here's an overview of thin section analysis in petrography:

Sample Preparation: The process begins with the preparation of a thin section, which involves cutting a thin slice (typically 30 micrometers thick) from a rock sample and mounting it on a glass slide. The thin section is then ground and polished to achieve a precise thickness and a smooth, transparent surface suitable for microscopic examination.

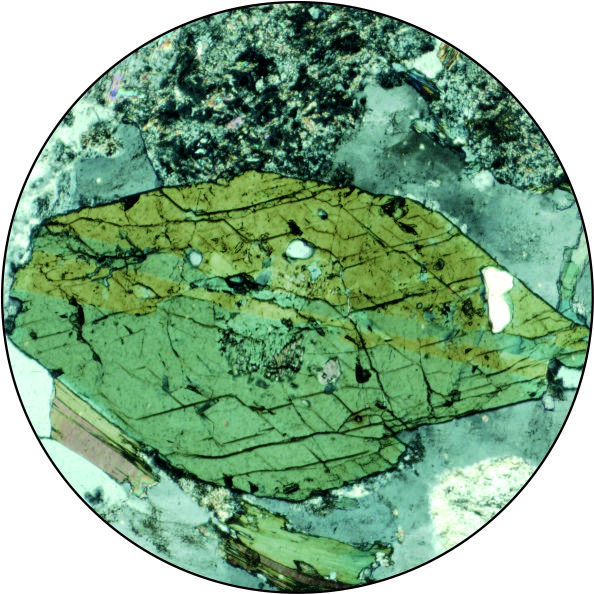

Microscopic Examination: The prepared thin section is examined under a petrographic microscope, which is equipped with polarized light and other specialized optics. By observing the interaction of light with the minerals in the thin section, petrographers can identify various minerals and determine their abundance, distribution, and relationships within the rock.

Mineral Identification: Petrographers use the optical properties of minerals, such as color, birefringence, and extinction angles, to identify and differentiate between different mineral species. This information is crucial for classifying rocks and interpreting their formation processes and geological history.

Texture Analysis: Thin section analysis allows for the detailed examination of the rock's texture, including the size, shape, and arrangement of mineral grains, as well as the presence of any deformation or alteration features. Texture analysis provides insights into the rock's crystallization history, deformation events, and subsequent geological processes.

Quantitative Analysis: In addition to qualitative observations, thin section analysis can also involve quantitative measurements, such as determining mineral proportions, grain sizes, and other textural parameters. These quantitative data can be used for statistical analysis, geochemical modeling, and comparative studies.

Interpretation and Correlation: The findings from thin section analysis are integrated with other geological data, such as field observations, geochemical analyses, and geochronological data, to develop comprehensive geological models and interpret the rock's history and evolution. Thin section analysis also facilitates the correlation of rock units across different locations and geological formations.

Thin sections Petrography in Poland

The rock petrography examination with thin sections analysis in Poland was started by polish Proffesor F.Kreutz (1844-1910) in 1868 at University of Lwow (today Ukraina before II WW Poland).

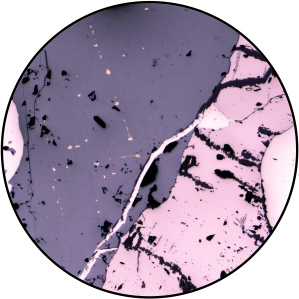

Polished thin sections

The polished thin sections are dedicated for reflected light microscope obserwations. This type of thin sections or thick sections (optional) is prepared on glass and is not cover with high quality of polished surface. The price is from 30 Euro per each, the most expensive which are prepared with special dry methodology, or the most hard rocks are the most expencive. |

|

Ordynary thin sections

Producing ordinary thin sections for petrographic analysis involves several specialized steps to ensure that the resulting sample is of high quality and suitable for microscopic examination. Here's a general overview of the process:

Sample Selection and Cutting: Begin by selecting a representative rock sample for analysis. The sample should be free from weathered surfaces, fractures, and other irregularities that could affect the quality of the thin section. Use a rock saw or a diamond-bladed trim saw to cut a flat, square piece of the rock sample.

Mounting the Sample: The cut rock sample is then mounted onto a glass slide using a suitable adhesive, such as epoxy resin. Ensure that the sample is securely attached to the slide and that the mounting surface is flat and even.

Grinding and Polishing: The mounted rock sample is ground down to achieve a thickness of approximately 30 micrometers, which is the standard thickness for thin sections. This process is typically performed using a grinding wheel or a lapping machine with progressively finer grit sizes. After grinding, the sample is polished to a smooth, mirror-like finish using a polishing wheel and a fine abrasive material, such as diamond paste or alumina powder.

Dicing: Once the sample has been polished, it is carefully diced into individual thin sections using a precision saw or a diamond-bladed wafering saw. Each thin section is separated from the mounting slide and cleaned to remove any residual adhesive or polishing residues.

Final Inspection and Quality Control: Before use, each thin section should be inspected under a microscope to ensure that it meets the required quality standards. Check for uniform thickness, absence of defects, and overall clarity of the section.

Labeling and Documentation: Finally, label each thin section with relevant information, such as sample name, location, and preparation date. Document any observations, such as mineral identification, texture characteristics, and other pertinent details, to facilitate subsequent analysis and interpretation. |

|